Often in the beef industry, producers de-prioritize their own physical and mental health. It’s easy to justify sacrificing our own wellbeing for the sake of getting the job done. But what if leaving humans last on the list has an impact on more than just people?

Dr. Michelle Calvo-Lorenzo is the Chief Animal Welfare Officer for Elanco. With much experience in the feedlot realm, Dr. Calvo-Lorenzo gained an interest in how humans interact with livestock. Now, she has a wealth of knowledge surrounding the impact of human mentality on animal welfare.

Unfortunately, animal welfare is a term without a consistent definition and means many different things to different people. Dr. Calvo-Lorenzo prefers the definition used by the World Organization for Animal Health (WOAH), which explains animal welfare as “the physical and mental state of an animal in relation to the conditions in which it lives and dies.”

“What I love about that definition is that it takes into account two important things,” says Dr. Calvo-Lorenzo . “One, that we have to use science-based evidence in order to determine the quality of life for an animal in different areas, including the mental state. But also, just as importantly, this definition is the first I have seen that integrates and honors the importance of humane care for animals throughout their life.”

Often, we only think of animal handling as the times where we bring cattle through a squeeze chute. However, as Dr. Calvo-Lorenzo explains, animal handling encompasses every point of interaction that we have with cattle, including euthanasia, feeding or cleaning water tanks, or even something as simple as walking through a pen to check cattle. The goal must be to aim for positive human-animal interactions every time, Dr. Calvo-Lorenzo explains, and cattle caretakers can achieve this if they recognize that cattle handling encompasses every way we approach cattle through tactile, auditory, and visual interactions.

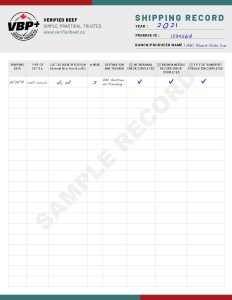

The VBP+ program has entire modules that focus on how to decide which animals are fit for transport or may need to be humanely euthanized. These are judgement calls that rely on human decision-making, and therefore can be influenced by how a person feels, acts, and thinks.

There are many theories about animal welfare out there, but Dr. Calvo-Lorenzo’s preferred model is the Five Domains (Nutrition, Environment, Health, Behavioural Interactions, and Mental Domain). This model is intended to provide a coherent assessment of animal welfare, including both the avoidance of negative outcomes and enhancement of positive outcomes relative to animal welfare status. In addition, it’s the first model that accounts for the animal welfare implications of human-animal interactions.

A study performed by Texas A&M researchers determined that employees like pen riders and doctors who work more frequently with cattle tend to perceive beef cattle more poorly (Ridge, Gill, & Daigle, 2019). Processors had poorer satisfaction with their jobs and less comfort with euthanasia. Despite high levels of knowledge and experience, the study noted that staff were typically underpaid and overworked.

Working conditions impact how stock people feel about their jobs and the animals they work with. Texas A&M researchers have also noted that investing in more than skills training, such as reinforcing the value of an employee’s work, positively impacts their attitude towards livestock and in turn, animal welfare outcomes.

“Attitudes, beliefs, and perceptions about the animals you work with all motivate behaviour,” explains Dr. Calvo-Lorenzo. “And the behaviours of people are what is imposed on the animal. So, if you have a person that believes that animals should be treated with respect, then that will influence the way they approach the animals.”

Of course, taking the time to offer training and maintain a positive workplace takes time and sometimes money. But as data shows, when employee attitudes change, not only do livestock fear states decrease, but productivity increases – that’s a positive to your bottom line.

Today’s labor gap is a challenge, and keeping skilled workers on your operation is key. Training a new employee after losing a good worker is costly, and is another reason why worker mentality matters to the bottom line.

“The culture of an operation is incredibly important,” says Dr. Calvo-Lorenzo. “With the right culture in place, not only will people do things right, but they’ll be motivated to do things better and better every day. And this enhances the culture, which feeds into a positive cycle where worker morale isn’t low, people aren’t going to cut corners, there’s loyalty to the operation, and turnover rates are reduced.”

While in an ideal world, every producer and their employees would have a small, manageable workload and a high budget for salary, bottom lines are tight and it can be tough to find experienced workers. But salary isn’t everything. “In the US, we’ve met people who are willing to work for slightly less per hour at an operation if the workplace culture is a better fit,” explains Dr. Calvo-Lorenzo.

Workplace culture is easy to picture in a formal business model, but what about in a scenario where staff is family, like so many Canadian beef cattle operations? “My advice for this scenario is to prioritize expectations for maintaining a professional workplace and treating each other with respect as professionals,” says Dr. Calvo-Lorenzo.

In the VBP+ standard, a code of ethics and training for people on the operation are encouraged. For many producers, these elements seem like something meant for the corporate world and feel too structured and rigid for the family feel we are used to. However, a positive and professional workplace culture can take the form of an unspoken atmosphere of respect and value in the work being done.

Creating a team of people committed to doing their jobs to the best of their ability can make a real difference to the viability of your operation. This approach makes managing healthy, content, and productive cattle the priority, with the added benefit of keeping your people healthy, content, and productive too.

Sources

Ridge, E. E, Gill, R., and Daigle, C.L. (2019). Evaluation of the Texas Feed Yard Workforce: Survey of Stockperson Attitudes and Perceptions towards Euthanasia, Animal Care and Employee Value. American Journal of Animal and Veterinary Sciences, 14(2), 139-150. https://doi.org/10.3844/ajavsp.2019.139.150